SCM STEFANI KD ERT EDGEBANDER

Stock Number:

14510

Condition:

CLEANED/CHECKED

Electrical:

230V, 3 Ph, 60 Cy

FOB:

Sanford, NC

Replacement Cost:

~$124,000

Our Price:

$0

Freight Charges Not Included

- PRIMARY SPECIFICATIONS:

- Edgebanding thickness: .4 mm to 12 mm

- Guillotine capacity: 3 mm

- Feed speed: 33 to 66 FPM

- Panel height: 3/8" min to 2-3/8" max

- Minimum panel length: 5-1/2"

- Minimum panel width: 2"

- Minimum distance between panels: 24"

- MAJOR FEATURES:

- Startouch controller features a 12” touch screen display. Capable of storing 100 programs, 6 at the touch of a single key. Color graphic display of all the working units. Tracks production info, diagnostic info, and monitors maintenance schedules

- Air Cushion Table at machine entry

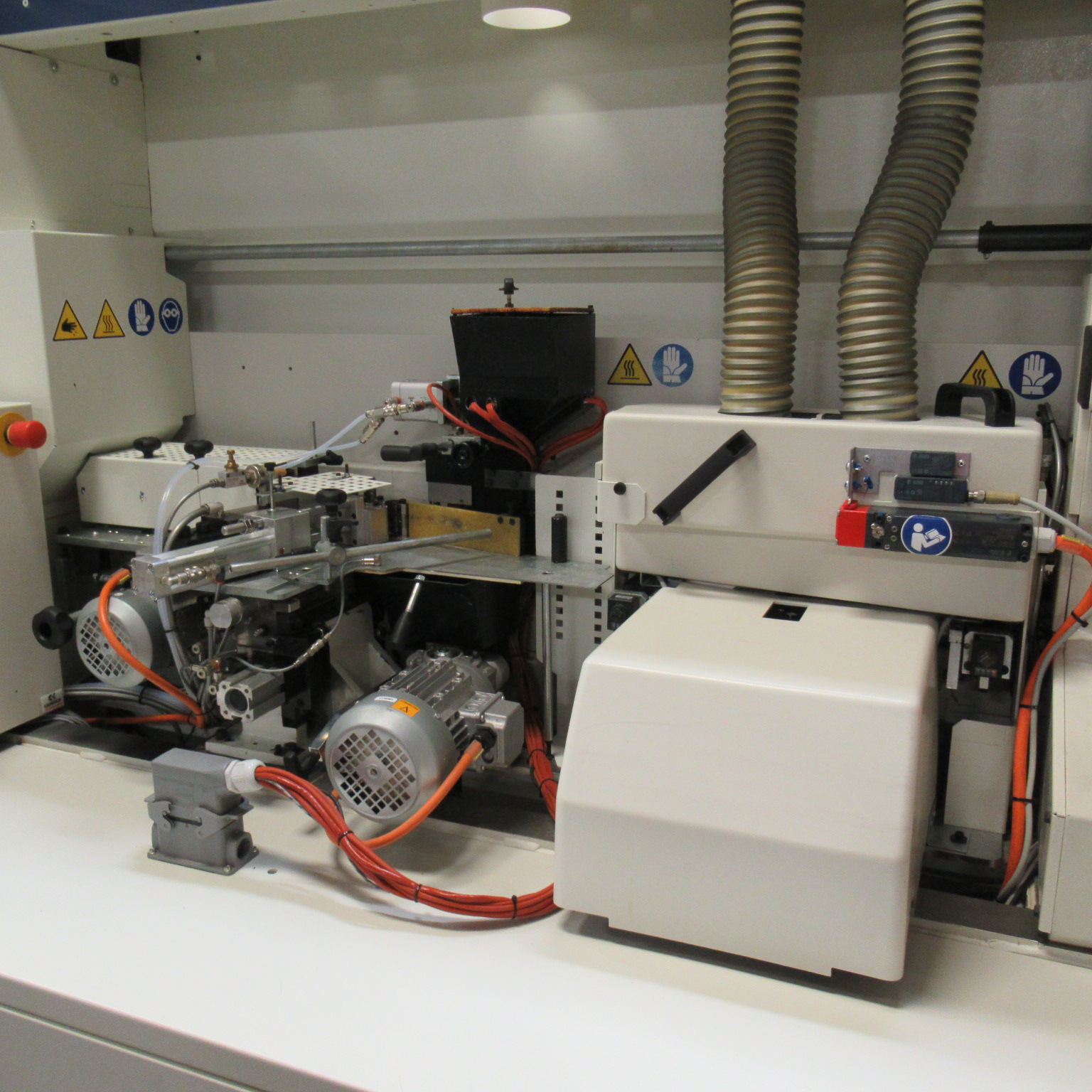

- SGP-E Glue Pot - Quick heat up time due to the small glue pot. Reverse rotation of the glue roller for the application of solid wood. Double Thermo Regulation for easy use of both EVA and PUR glue. Color change and glue pot cleaning are able to be completed in minutes, as opposed to hours.

- Lighted Sound Enclosure with Acoustical Hoods

- Anti-adhesive unit positioned prior to pre-milling unit prevents buildup of glue on top and bottom of panel

- Strip feed magazine

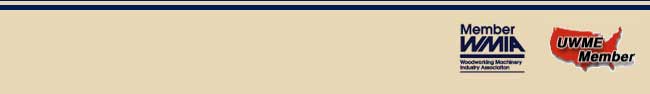

- "RT-E" Pre-milling station with (2) 3.0 HP motors, to rectify/clean panels already sized

- Pressure station with pneumatic driven roller and (3) spring loaded idle rollers

- "K-SEL 2" End trimming station with (2) independent 0.50 HP motors mounted on THK guides

- Servo driven top and bottom trim station composed of (2) independent 1 HP motors operating at 12,000 RPM

- "Round-K" corner rounding unit composed of (2) independent 0.80 HP motors that slide on THK guides

- "RAS/1000" profile scraping unit designed to remove knife marks, equipped with pneumatic in/out positioning through controller

- Glue Scraping unit

- "SPN" Buffing unit consisting of (2) independent 0.25 HP motors

- Air requirements: 90 PSI

- Dust collection: Working units are individually ported on the top of the safety enclosure for maximum efficiency.